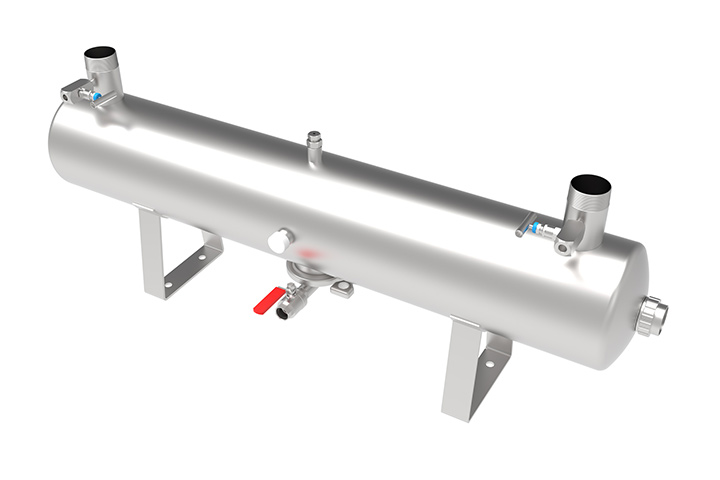

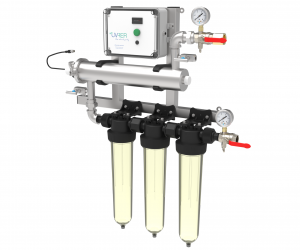

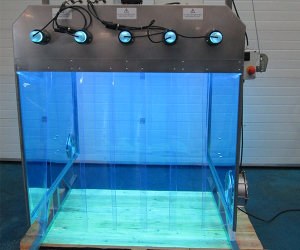

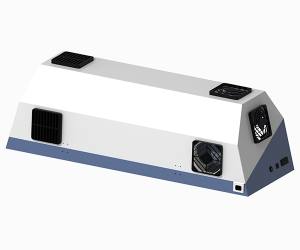

Arboriculture, horticulture, aquaculture, breeding, dairy industry … Since 1982, UVRER has specialized in UV technology (type C) (for water treatment and surface disinfection) and in photocatalysis (for air purification) which allows us to offer chemicals free solutions. Those clean and reliable technologies respect the health of users and the environment: ultraviolet does not generate any harmful by-products. We therefore offer many ranges of water treatment, air purification and surface disinfection devices, and we also often produce tailor-made modules adapted to our customers’ needs.

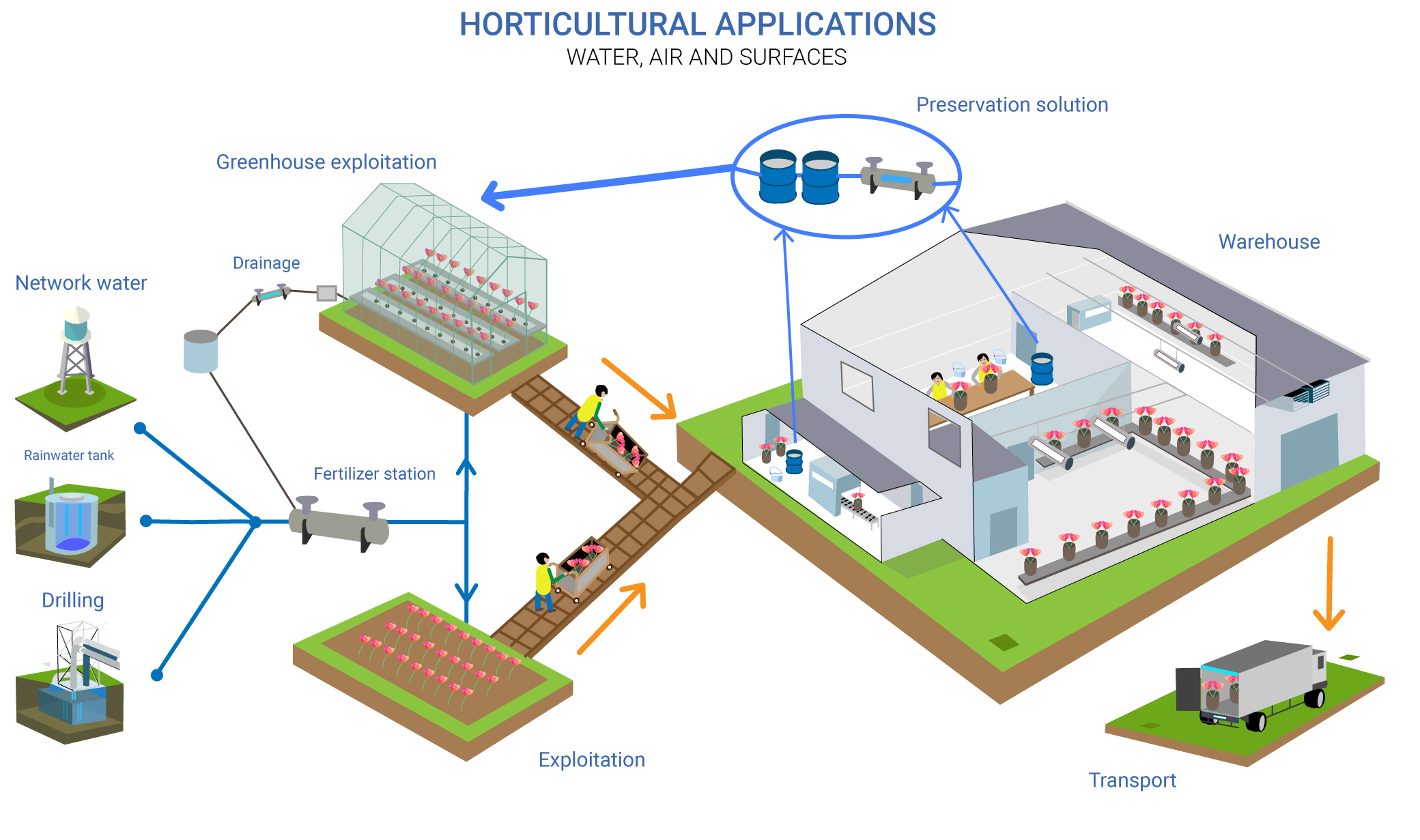

Our goal: to enable you to reduce or even completely eliminate chemicals in your process. Thanks to our three complementary activities which are water, air and surface treatment, we are able to intervene at different stages of your production process (see the diagram below which illustrates the diversity of our field of action , here for horticulture but available for multiple applications).

English

English Français

Français Español

Español