In cheese making, the few liters of water used for each liter of processed milk are mainly used for cleaning, disinfection and rinsing of equipment.

Any micro-organism present in the water used can therefore contaminate surfaces and subsequently products. However, beyond the potability (and/or cleanliness) criteria imposed by regulations, water, whatever its origin, is likely to have high concentrations of certain spoilage flora such as Pseudomonas.

Water quality must therefore be considered as a major issue for the health and organoleptic quality of products, and its control constitutes an essential point in the quality approach of today’s cheese factories.

A tailor-made expertise

Our devices use UV-C radiation which treats and disinfects different types of water (process water, tank cleaning, effluent) to ensure optimal hygiene and disinfection and limit environmental pollution, by reducing the use of chemicals.

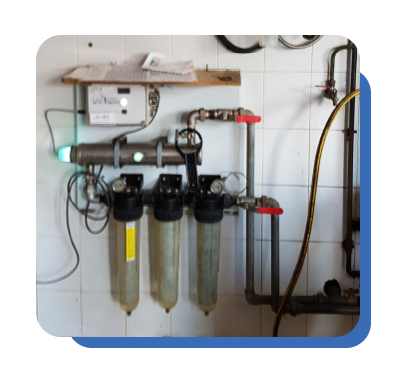

Modular installations are protected by flow limiters, so that the dose always remains appropriate. Filters, placed in front of the UV, are added according to customer request, from 5 to 25 microns, in order to reduce suspended matter in the water and optimize the effectiveness of the UV.

We work directly with our customers, but also through many retailers.

Discover our Dairy Station

Developed specifically for dairy and cheese producers, this station allows optimal treatment of the water used during the cheese manufacturing processes.

- Available in 55 and 95 Watt versions

- Maximum flow: 4 m3/h

- 316L stainless steel treatment chamber

- Clamped body for easy maintenance

- Nominal pressure: 6 bars

- Integrated filter holders

Many cheese factories already use our station to secure their production and protect themselves from Pseudomonas and fungi which can contaminate an operation in a very short time and jeopardize its production.

Advantages of the UV-C technology

- Effective on all types of micro-organisms, including Pseudomonas

- Optimal machine sanitation

- Natural and ecological process, respectful of people and the environment

- Reduction in chemical consumption

- UV-C radiation acts instantly, without risk of overdose

- Reduction of waste thanks to the long lifespan of UV-C lamps

- No modification of the physicochemical criteria of the fluids

- Without side effects or generation of harmful by-products

- Modular technology, depending on your specific needs

- Simplified installation and maintenance

Our references

English

English Français

Français Español

Español