A few months ago, our design office focused its actions on improving our FZI range, designed for the purification of industrial water with ultraviolet (UVc): agro-food, communities, chemicals, pharmaceuticals, process water, effluents, etc. We have therefore developed the new DFI range, using Fluid Dynamics Calculation (CFD) software. Easier to maintain and more efficient, the range effectively enhances hydraulic performance and achieves significant energy savings.

With a disinfection capacity ranging from 15 to 130m2, the DFI adapts to a wide range of applications. This new range offers many benefits:

Better data accuracy: The use of CFD (Computer Fluid Dynamics) software can accurately simulate the flow of fluids and UVc radiation inside our devices. We follow each possible trajectory and calculate the residence time and the perceived dose for each organism passing through the device.

Easier maintenance: Taking into account all these parameters allowed us to design deflectors that facilitate the quartz insertion inside the device and allow a higher permissible flowrate. It is specifically efficient in case of troubled or dirty water to allow a better transmission of UVC light.

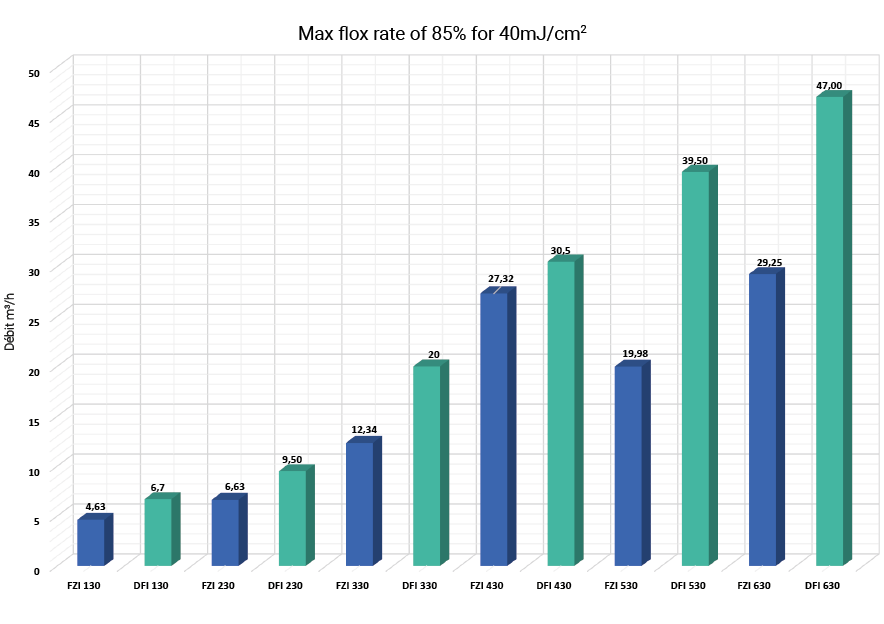

Significant energy savings: Thanks to accurate data collection, we have managed to improve our devices performances and thus reduce the energy consumption required. Indeed, the flow rate of the DFI 530 for example has increased considerably compared to the FZI 530, while the energy required is equivalent (see the histogram below).

The DFI range: designed and manufactured in France.

English

English Français

Français