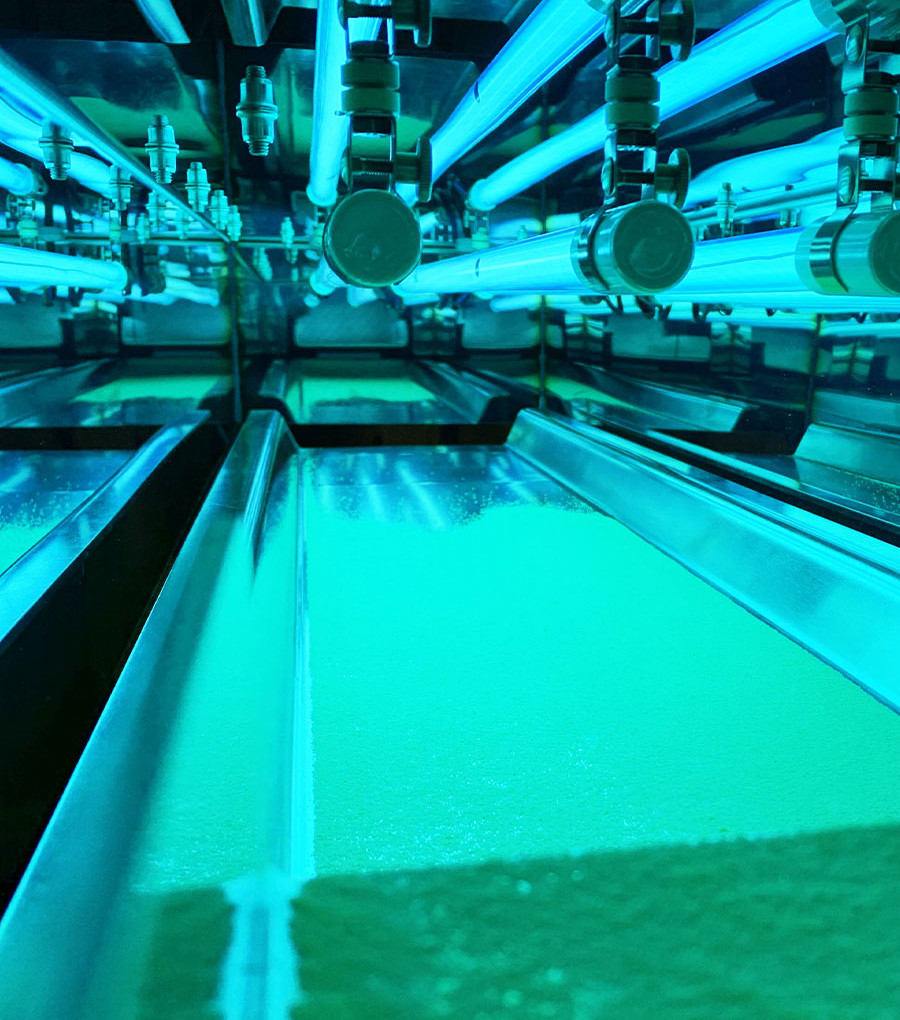

Since 1982, UVRER has designed and manufactured UV treatment devices for the disinfection of fluids (water and air) and surfaces. This is a technology that is harmless to human and animal health and the environment. Microorganisms are deactivated without the use of chemicals (or, depending on your needs, reduces their use). Our UV and photocatalytic systems come from French industrial and university research.

We take care of your projects, from design to completion:

- R&D and engineering: development of innovative and efficient solutions, technological monitoring

- Design office: definition of the concept, studies, sizing and design

- Welding: welding of stainless steel, carrying out specific mechanical welding

- Quartz: shaping quartz for specific applications

- Control and quality: electrical and hydraulic tests carried out on all of our ranges

TECHNOLOGIES

- Filtration: after passing through the pre-filter (allowing dust and other particles to be retained), the air then passes through an activated carbon filtration system, known for its ability to adsorb volatile organic compounds or VOCs.VOCs are molecules dissolved in the air, which constitute very harmful pollutants for indoor air (odors, chemical compounds and all kinds of harmful gases).

- Ultraviolet: UV radiation has the ability to destroy germs (microbes, viruses, bacteria, fungi, mold, etc.) contained in fluids. Indeed, UV-C radiation crosses the cytoplasmic membrane of the cell and penetrates the nucleus. When cells divide, the DNA is unable to replicate or reproduce. Its molecular structure is thus broken and renders the microorganism harmless.

- Photocatalysis: helps destroy all polluting particles in the air. Through the generation of oxidizing radicals, this process causes the chemical bonds of pollutants (VOCs) to break. These are then degraded into H2O and CO2 which are harmless to humans. Photocatalysis acts both on the chemical molecules blocked by the activated carbon filter and on those which pass through it. The combination of the two technologies ensures optimal decontamination of microorganisms.

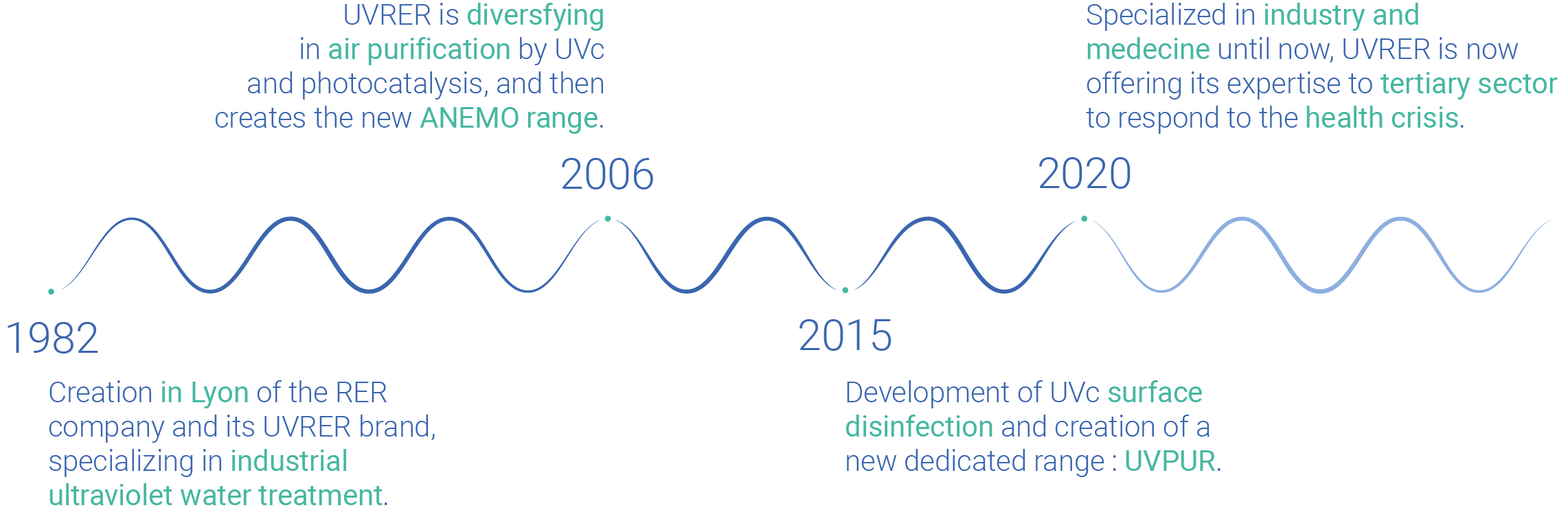

OUR HISTORY

Les COV sont des molécules dissoutes dans l’air, qui constituent des polluants très nocifs pour l’air intérieur (odeurs, composés chimiques et toute sorte de gaz nocifs) .L’ultraviolet : les rayonnements ultraviolets ont la capacité de détruire germes (microbes, virus, bactéries, champignons, moisissures…) contenus dans l’air.

En effet, les rayonnements UVc traversent la membrane cytoplasmique de la cellule et pénètrent dans le noyau. Quand les cellules sont divisées, l’ADN est incapable de se répliquer ou de se reproduire. La structure moléculaire de l’ADN est ainsi brisée et rend inoffensif le microbe

OUR QUALITY APPROACH

Since its beginnings, the UVRER company has undertaken a quality and continuous improvement approach to its UV installations. These provide total security to the user, with equipment that meets the strictest standards in terms of:

- Electrical and electromagnetic safety: equipment compliant with CE standards

- Food safety: materials compatible with current legislation concerning the food sector (stainless steel, quartz, gasket, etc.) and “drinking water suitability”

- Germicidal safety*: materials developed in compliance with the legislation of the French Ministry of Health, applicable to international standards, relating to the disinfection of water intended for human consumption by UV rays

- Hydraulic safety: production of all of our equipment on the production site in Saint-Genis-Laval: assembly, quartz (rounded bottoms, etc.), tanks (stainless steel, PVC) Materials systematically tested leaving our factory on our hydraulic and electrical test benches

*In accordance with the decree of October 18, 2012 of the French Ministry of Health, our devices guarantee the delivery of a minimum dose of 40mJ/cm2 for the treatment of water intended for human consumption.

English

English Français

Français Español

Español