UVRER air treatment systems (ANEMO range) are based on three technologies: filtration / adsorption, ultraviolet and photocatalysis, referred to as the TRI-ACTIVE technology. These are environmentally friendly processes that work without the use of chemicals or gases.

Our products are also equipped with a pre-filter to retain dust and other particles present in the air. After passing through the pre-filter, the air then passes through an activated carbon filtration system. Activated carbon is known for its ability to adsorb volatile organic compounds or VOCs. VOCs are molecules dissolved in the air, which are very harmful pollutants for indoor air; among them, odors, chemical compounds and all kinds of harmful gases. Activated carbon adsorbs up to 10% of its mass in pollutants: it thus contains pollution peaks.

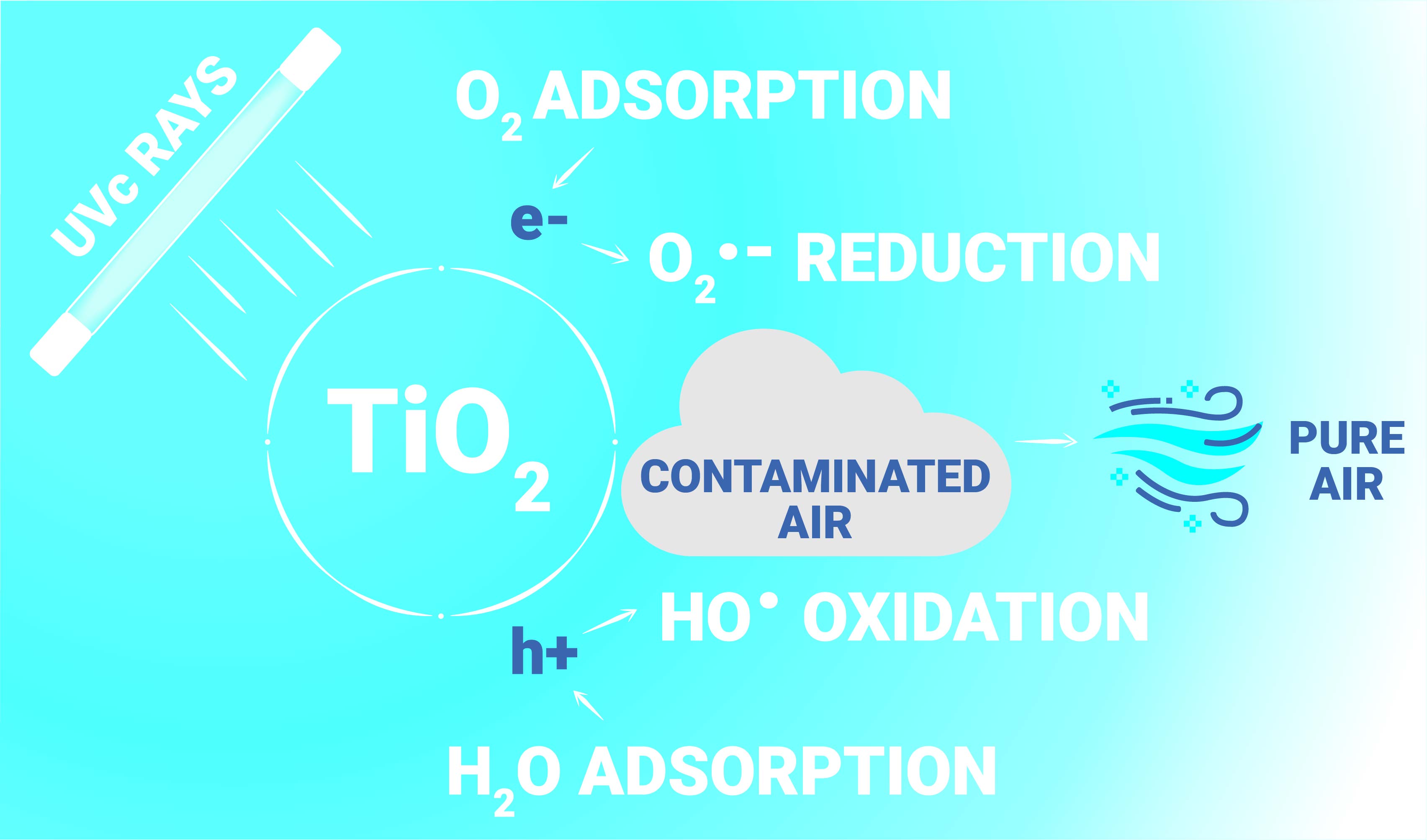

Air treatment by photocatalysis combines UVc radiation with a photocatalyst: TiO2. TiO2 has many advantages such as its efficiency, its non-toxicity, its stability as well as its low cost. Activation of TiO2 by UVc leads to the formation of radicals allows the degradation of a wide range of pollutants including Volatile Organic Compounds (VOCs). VOCs are direct pollutants for humans and plants. By choosing ANEMO technology, which involves photocatalysis, you help creating an healthy air without the use of chemicals. The figure below summarizes all the reactions occurring on the surface of a semiconductor, TiO2, under the action of adequate UV radiation.

ADVANTAGES OF AIR TREATMENT BY PHOTOCATALYSIS

- Ecological process respectful of the environment.

- Effective for microorganisms (including the Coronavirus family) as well as for VOCs such as ethylene

- No secondary pollution by ozone discharge. On the contrary, UV-C radiation degrades ozone

- Air treatment in all spaces, wide range of products allowing the adaptation of equipment in all types of structure.

- Significant reduction in the risk of diseases (respiratory diseases, SARS, cancers) linked to bacteria present in the air.

- Cost reduction: Reduced energy consumption for heaters and air conditioners as photocatalysis prevents them from clogging.

- Efficiency: The annular / tangential flow reactor increases the passage time of microorganisms and allows optimal exposure for the activation of microorganisms and the mineralization of VOCs by photocatalysis / UVc

- Improved comfort for occupants of treated spaces and reduced risk of contamination.

- Does not charge the air with free radicals: radicals are generated on the surface of TiO2 and are quickly consumed by degradation reactions

- Does not require any additional safety device and can be used without risk in the presence of personnel

- Safety of use: UVc are contained within the device, totally harmless for all operators (safety validated by independent organism)

- Return on investment: 1 month out of 5 months of storage and a production loss limit of 15% to 40%. Also limits product weight loss during storage.

- Photocatalysis generates hydroxyl radicals which have a greater oxidation potential than ozone (2.8V against 2.07V) which allows better degradation of pollutants.

EXAMPLES OF APPLICATIONS

Chemistry

As air is an asset to preserve, the ecological solutions developed by ANEMO (UVRER’s air treatment activity) have an important role to play in improving its quality. Thanks to our devices, it is now possible to treat industrial gaseous effluents before discharge into the atmosphere. ANEMO technology enables to reduce or even eliminate the emission of Volatile Organic Compounds in the atmosphere (eg: Benzene, Heptanal, Hexane, etc.). As the discharge thresholds are lower and lower, photocatalysis then appears as an innovative and efficient solution adapted to industrial problems.

Agriculture

ANEMO purification systems are designed to ensure the quality of post-harvest products during storage and thus:

- Limit product degradation

- Limit mass losses

- Limit the use of chemicals during storage.

- Increase the lifespan

The main problem with post-harvest fruits and vegetables storage is the presence of harmful elements in cold rooms and packing areas. In addition to the development of microorganisms, the emission of ethylene also accelerates the degradation of products (especially for climacteric fruits such as plums, peaches, etc.). ANEMO solutions make it possible to respond to these two problems with a single air treatment device.

Transport

ANEMO “Transports” technological solutions offer you a guarantee of high atmospheric quality for :

- The transport of food and plants:

- Reduce airborne contamination between products

- Stop secondary contamination / pollution linked to internal air conditioning systems

- The travellers :

- Limit the impact of chemical pollutants contained in materials

- Reduce viral and bacterial contamination between travelers

- Stop secondary contamination / pollution linked to internal air conditioning systems

Examples of applications:

- Ambulance

- Standard truck

- Train

- Bus

- Refrigerated truck

Home

Materials, insulation, treatment and coating products, heating, air conditioning and furnishings that are part of an HQE approach are major sources of emissions of carcinogenic and mutagenic pollutants. ANEMO has developed a specific system which combines the most efficient air purification solutions. The integration of ANEMO solutions is the assurance of a healthy environment and high energy performance.

- Private house

- DIY workshop

- Private garage

- Cellar

Medical

ANEMO technological solutions offer you to reduce airborne nosocomial contaminations in risk areas, limit the health impact of chemical and microbial pollutants in environments and ensure the well-being and health of patients and practitioners. Our technical and scientific teams are at your disposal for the integration of ANEMO systems into your environments. We will be able to respond to your specific contamination, pollution, health / safety issues and will help you enhance your HQA (High Atmospheric Quality) approach.

- Consultation Cabinet

- Waiting room

- Treatment room

Viticulture

One of the main concerns in the wine industry is the appearance of a corky or musty-earthy taste. The consequences of these two alterations are significant economic losses due to a reduction in volumes but also customer dissatisfaction with the quality of the product. ANEMO develops air treatment devices that perfectly respond to the issues found in the wine industry. Indeed, the combination of adsorption on activated carbon and degradation by photocatalysis can effectively treat many chemical compounds including TCA, TeCA, TBA and geosmin responsible for corky and musty tastes.

- Cold room

- Industrial gaseous discharge

- Wine cellar

Public and collective places

ANEMO air purifiers are used to treat indoor air against bacteria, mold and other disturbing particles in all types of structures (public places, nurseries, schools, private homes, pet shops, etc.). Our systems also protect you against the risks associated with volatile pollutants such as formaldehyde, toluene, benzene which can lead to pathologies such as asthma, allergies and others. Indeed, it has been shown that contrary to popular belief, the air in confined spaces is 10 times more polluted than the air outside, because it is confined, which increases the concentration of pollutants in the air. ANEMO offers solutions for disinfection and deodorization of ambient air for collective living spaces that meet the requirements stipulated in the decree of December 21, 2011 of the Ministry of Ecology and Sustainable Development.

- Nurseries

- Public place

- Municipal toilets

English

English Français

Français Español

Español